The Company

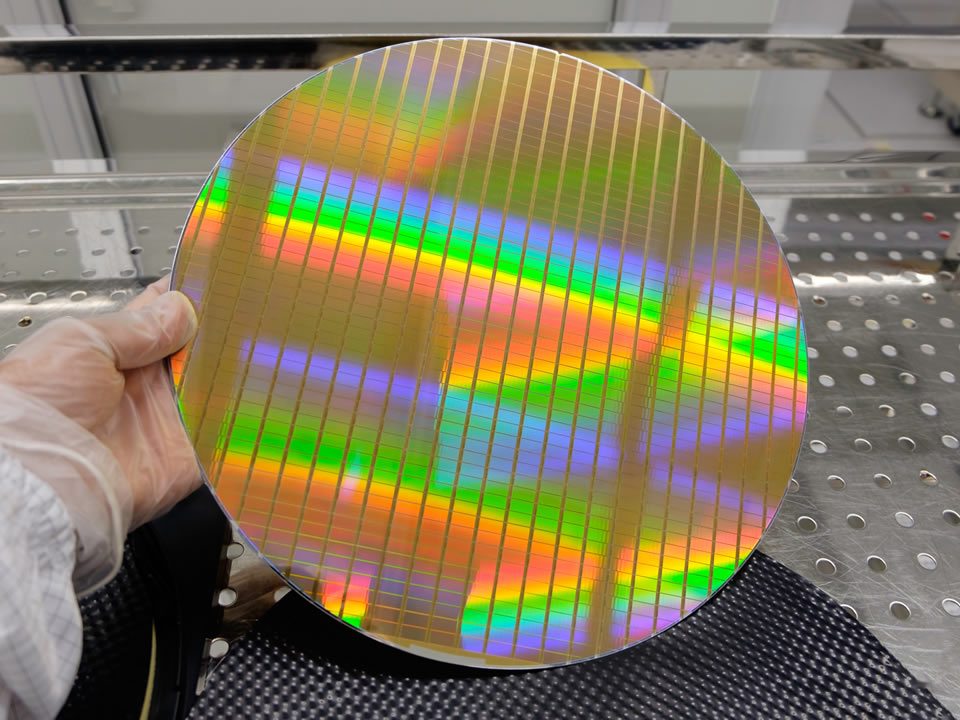

At Ding Cheng, we are dedicated to providing our customers with cutting-edge solutions that help them stay ahead of the curve in the semiconductor industry.

Since 2007, Ding Cheng has emerged as a reliable collaborator for foundries and research institutions within the global semiconductor industry. Specializing in the wet process domain, we offer comprehensive solutions ranging from spare parts to turnkey options for both single wafer and wet station tools. By collaborating with our clients and comprehending their requirements, we have successfully created various patented add-on systems that can boost yield or increase throughput on a wide range of tools.

Our fundamental principles revolve around "Innovation" and "Quality," and as we continue to develop products and systems to assist chipmakers in delivering superior products to society, we will maintain close partnerships with our customers and collaborators.

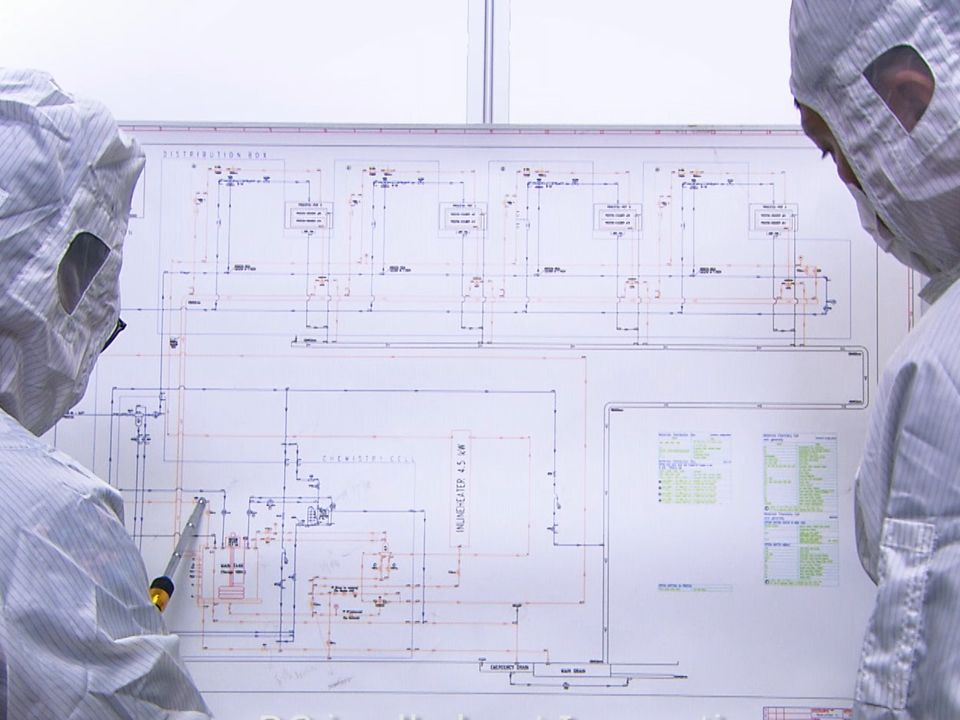

Our Team

At Ding Cheng, our team is composed of driven engineers with robust backgrounds in both process and equipment manufacturing. Each of our senior engineers is a specialist in their respective fields, and to guarantee quality, our engineers must undergo a series of training and assessments before participating in our clients' projects. To this end, we have dedicated equipment exclusively for staff training.

We aim to cultivate an environment in which intelligent, motivated, and imaginative individuals thrive, as evidenced by our clients' acknowledgment.

History Case

- Turnkey

- SEZ203 Turnkey

- SEZ203 Turnkey

- USHIO UV Turnkey

- SEZ 323 Turnkey

- KAIJO Wet Bench S/W Develop

- KAIJO WPH improve

- DNS Wet Bench S/W Develop

- DNS WS 820L

- SEZ DV34

- Retrofit

- SEZ4200 TMAH Retrofit

- SEZ203 Autofill function

- SEZ203 Retrofit , open cassette retrofit to SMIF type

- SEZ 323 Process Transfer Retrofit

- UV Curing tool add RTM system

- SEZ 323 refurbish for ST250

- SEZ 203 8”TO 6” Retrofit

- SEZ 4200 Recovery

- SEZ 323 Suckback system

- SEZ 203/223 FDC system

- SEZ223 Retrofit for DSP process

- SEZ DV34 S/W upgrade

- SEZ4300 Autofill function

- DNS FC3100 Computer upgrade

- DNS CARO’s Wet Bench O/H

- SEZ 203 O/H

- SEZ 4200 O/H

- SUGAI Dryer Replace

- KAIJO Software/Hardware retrofit

- SEZ223 Autofill function 2MED

- SEZ 4300 Robot upgrade

- SEZ323 DUMET5 CDS2 H/W&S/W modify(ST250分流)

- SEZ323 retrofit Prstrip for Clean improvement for FPRWS3

SEZ_203 CDS tank3 Recover - SEZ 4200 O/H&Retrofit

- SEZ 4200 Software Rebuilt&Recover

- SEZ4200 PC Upgrade

- SEZ323 Dispensor Angle Detect System

- Relocate

- SEZ4200 Relocate

- SEZ203 Relocate

- USHIO UV Relocate

- SEZ 304 Relocate

- SEZ 323 Relocate

- SEZ 305 Relocate

- SEZ DVP Relocate

- SEZ DV34 Relocate

- SEZ4300 Relocate

- DNS 820C Relocate

- DNS FC3100 Relocate

- Wet bench

- DNS WS820

- DNS WS 820L

- 8” KAIJO

- 8” SES (ongoing)

- 12” FC3100 Relocation

- 12” FC3100 Relocation