MERCURIUS 4

- Features

- With four chambers, our T342 significantly increases wafer production capacity within a given time frame.

- The T342 offers flexibility in configuring process acid types, with the capability to use up to three different types of acids. It also features a layered recycling design, separating acids from other liquids to avoid cross-contamination. The T342 is capable of high-temperature processes with each acid supply module featuring two 6kw inline-heaters for efficient heating. Our flexible process recipes are highly customizable, with all three XYZ axes on the spray equipment equipped with servo motors to provide precise and rigorous process conditions. The modular design of the T342 makes it easy to modify and adapt to the specific needs of our customers.

- Choose our T342 for reliable, efficient, and flexible wafer etching and cleaning.

Description

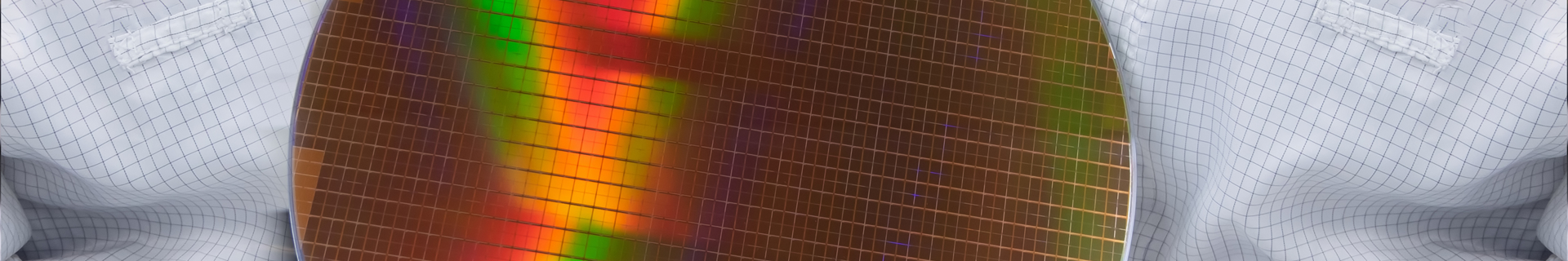

A wet etching single-wafer 4-chamber process equipment designed for 12-inch wafers used for etching and cleaning in the semiconductor wafer fabrication process.